Call : 08045801215

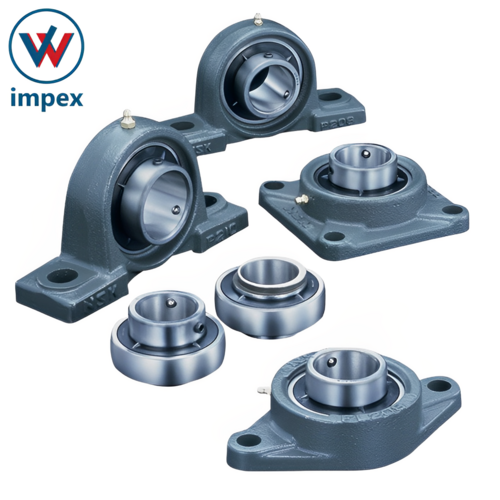

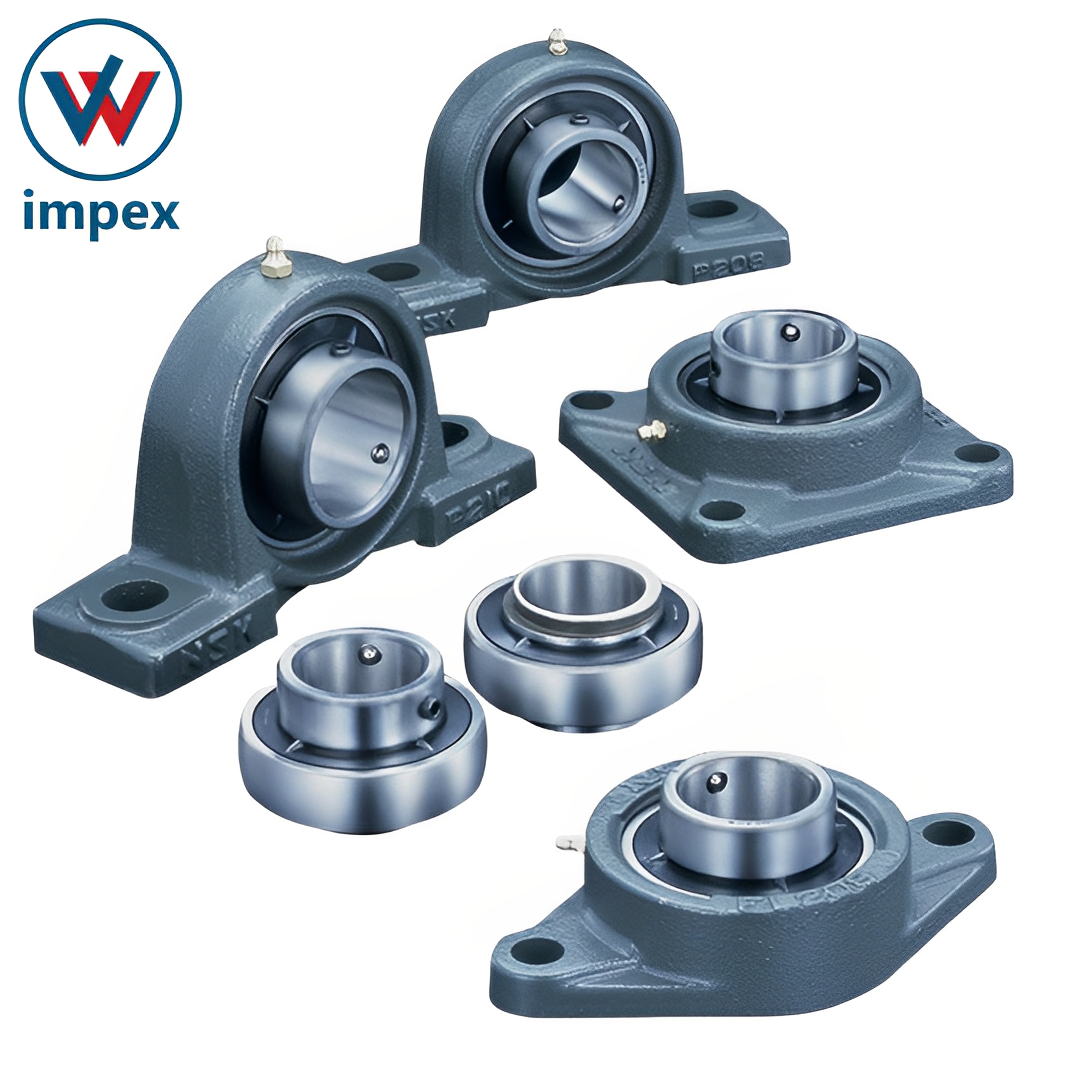

SLB Bearing Units

2500 INR/Piece

Product Details:

X

SLB Bearing Units Price And Quantity

- 2 Piece

- 2500 INR/Piece

Product Description

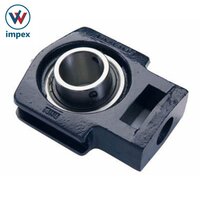

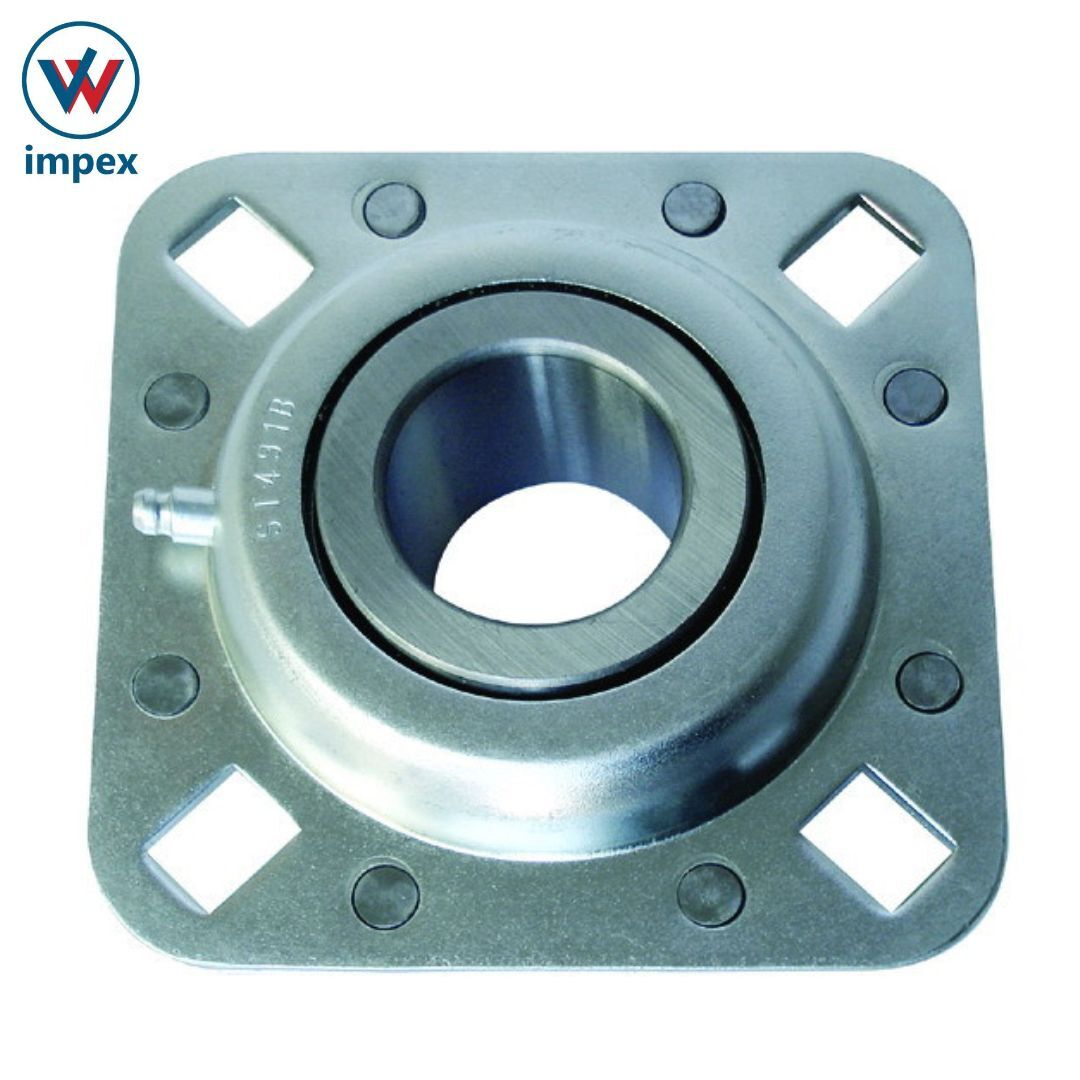

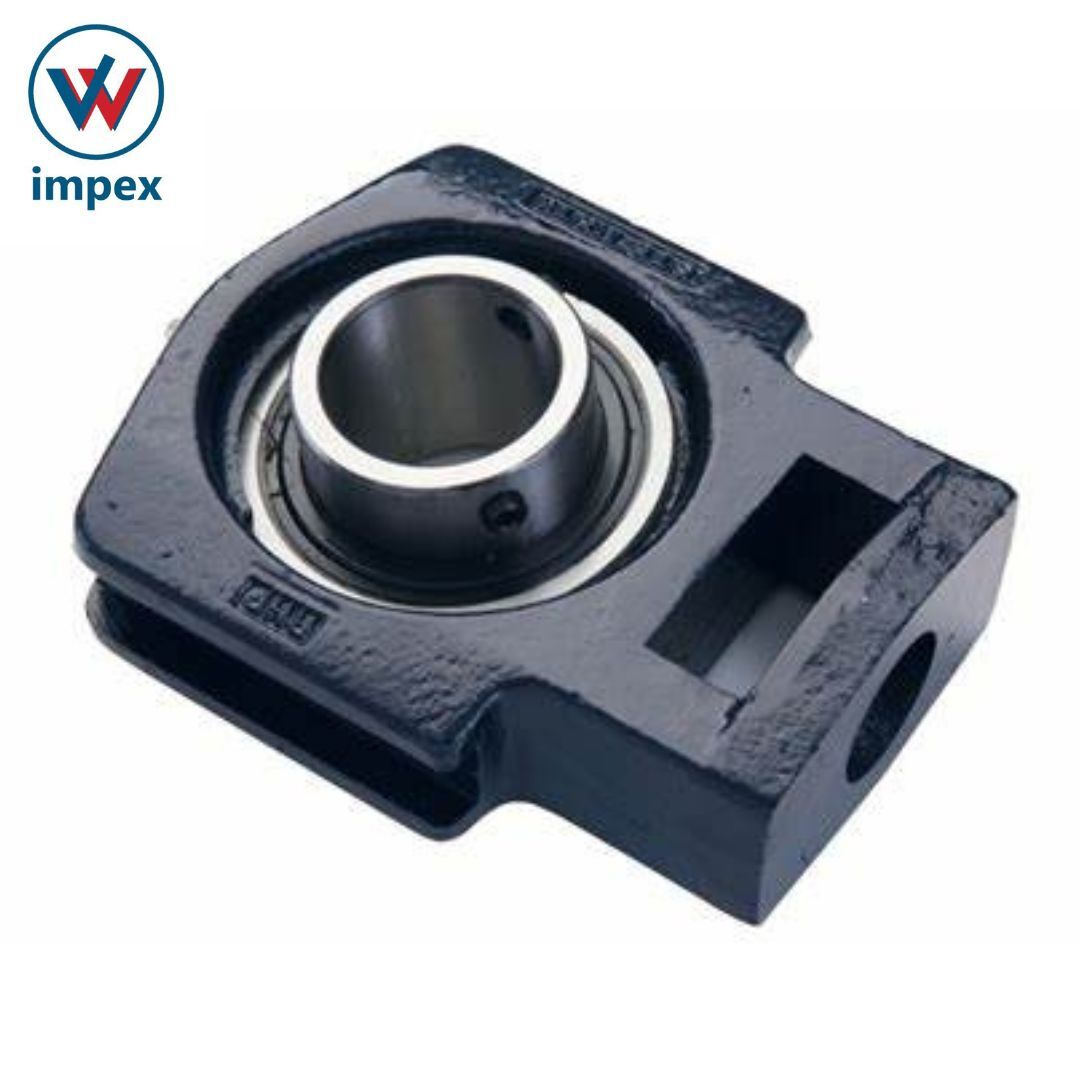

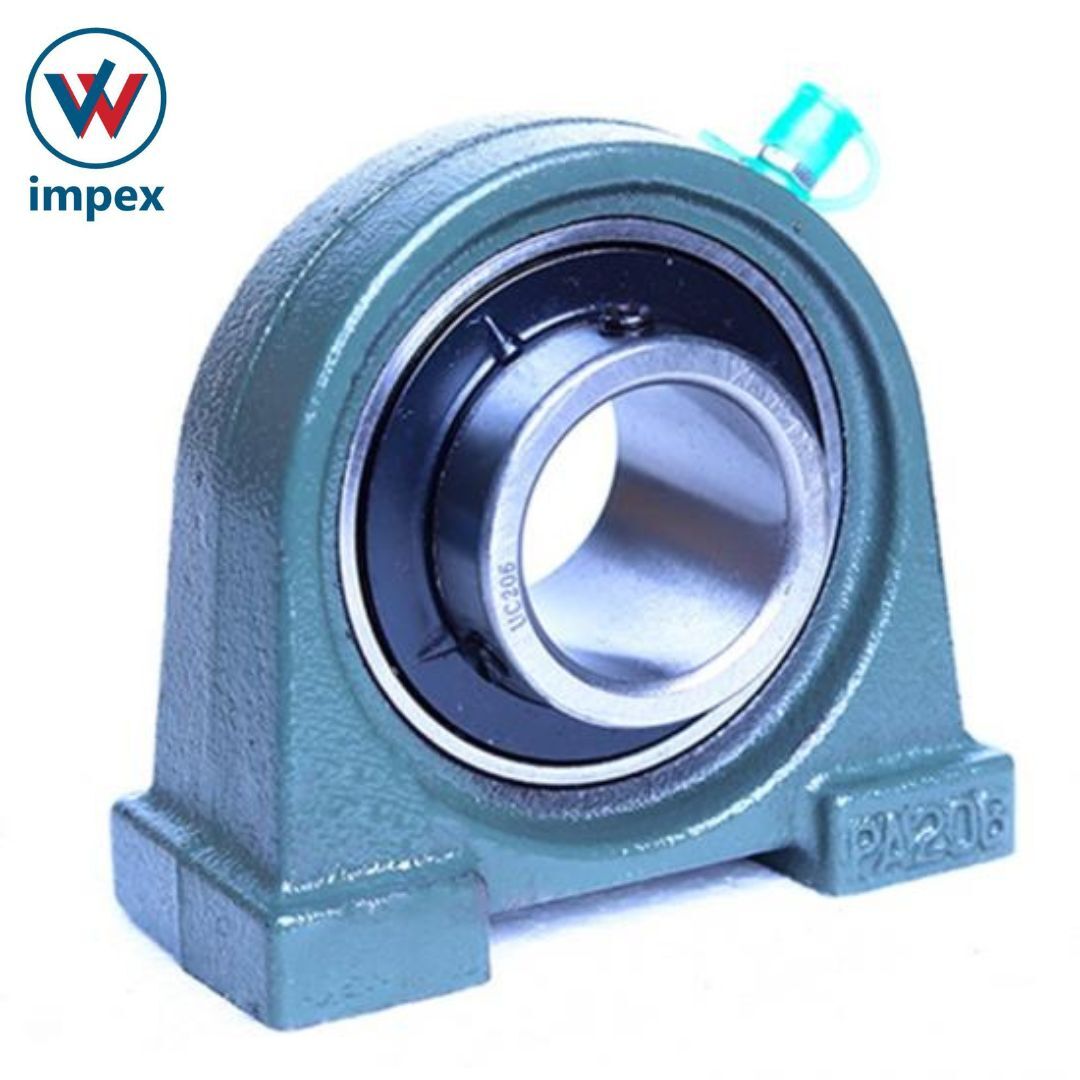

The housings are mainly casting housings. There are pressed steel plate housings as well align with ease during operation and can be conveniently mounted or dismounted. The bearing units can operate satisfactorily under working conditions, especially for machines operating in dusty or muddy surroundings. Thus, they are widely used in agricultural, construction and transmission machineries, etc...There are various types of sealing devices for our products, such as synthetic rubber seals, slinger with synthetic rubber seals and triple lip seals etc.. Sufficient lubricating grease has been put into the bearings during manufacturing, which can act as lubricating as well as rust proof. No more grease is needed to put in during the lubricating period when the bearings operate under normal conditions. Lubricating grease can be added from the fittings when the relubricate bearings operate under hard conditions. The outer ring of the bearing has spherical outside surface which can be fitted to the concave spherical surface of the housing, and the fit between them can be clearance fit or interference fit according to different conditions. This combination provides self-alignment between the self-contained bearing and the housing, and compensates for a certain alignment errors or flexing of the shaft when the bearing is in operation. This definitely increases the bearing service life.Enter Buying Requirement Details

Other Products in 'Bearing Units & Housings' category

|

V. W. IMPEX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry