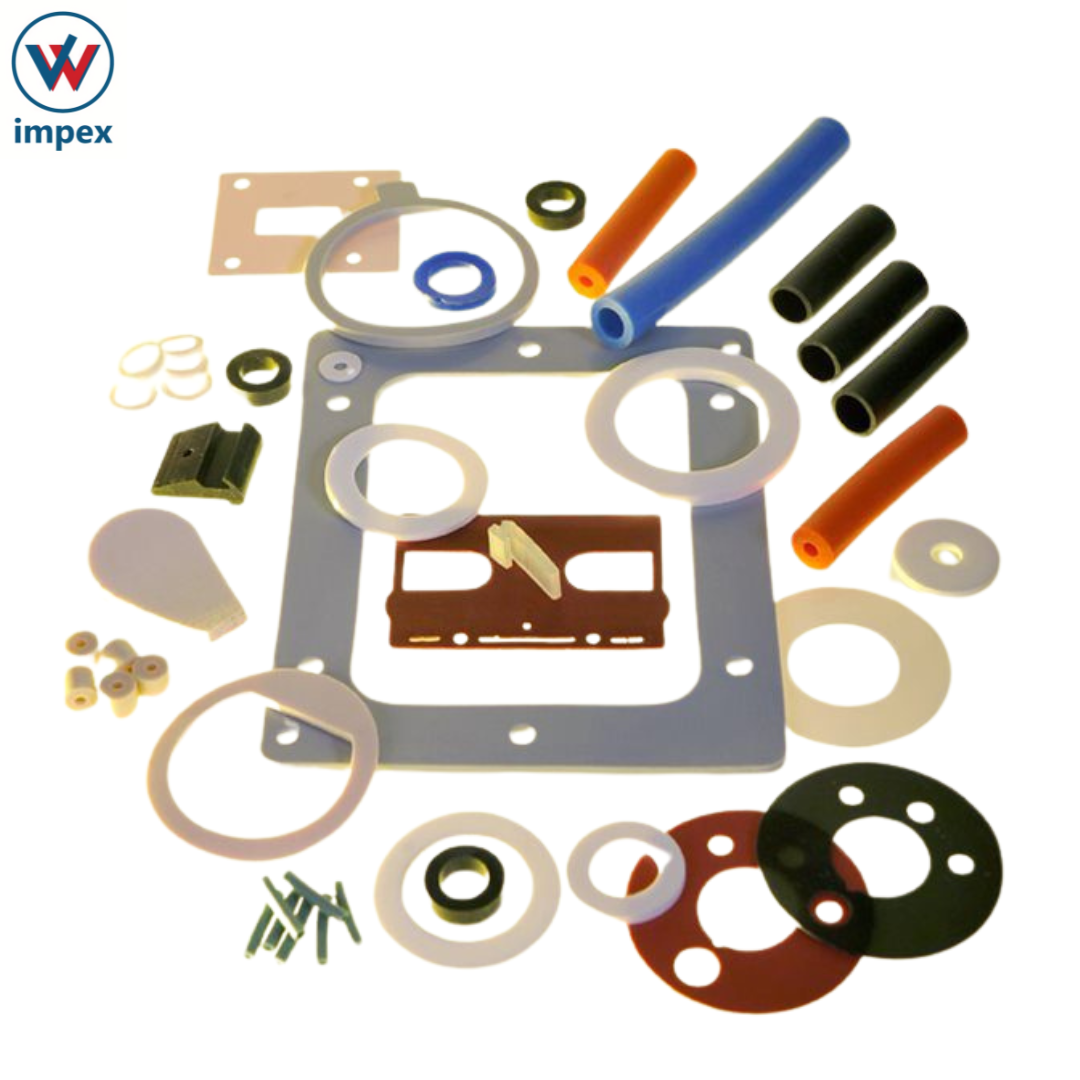

SILEX Limited Silicone Sheeting, Hoses And Seals

Price 8000 INR/ Piece

SILEX Limited Silicone Sheeting, Hoses And Seals Specification

- Lubrication Type

- Non-lubricated (Silicone inherently non-stick)

- Precision Rating

- High tolerance, 0.25 mm

- Thickness

- 0.3 mm to 12 mm (standard) or custom thickness

- Inside Diameter

- Custom on request (hose/ seal)

- Material

- Platinum or Peroxide Cured Silicone Rubber

- Structure

- Customizable (Solid/Sheet, Hose, Seal)

- Seals Type

- Silicone Seals (Flat/Custom profile)

- Bore Size

- Varies as per requirement

- Outside Diameter

- Up to 1200 mm or per customization

- Temperature Range

- -60C to +230C (intermittent up to +250C)

- Elongation at Break

- 350% (Approx.)

- Shore Hardness

- 30-80 Shore A (as required)

- Surface Finish

- Smooth, non-stick and non-reactive

- Typical Applications

- Medical, Pharma, Food Processing, Laboratory, Gasket & Sealing, Electrical Insulation

- Manufacturing Form

- Rolls, Strips, Gaskets, Hoses, Custom cut shapes

- Electrical Properties

- Good dielectric strength, suitable for insulation

- FDA Compliance

- Available in FDA-approved grades for food & pharma

- Color Options

- Translucent, Red Oxide, Blue, Custom shades available

- Tensile Strength

- 8 11 N/mm

- Odor

- Odorless, Non-toxic

- Water Absorption

- <0.5% (virtually non-absorbent)

About SILEX Limited Silicone Sheeting, Hoses And Seals

Silex was established in 1985, and is one of the UK's leading manufacturers of silicone-based products. They hold the country's largest stock of sponge and solid sheeting including FDA Sponge and Metal Detectable options.

Silicone Sheeting Products

Silex manufactures and stocks a comprehensive range of silicone sheeting from rubber in both solid and sponge grades. With hardness's from 10-90 shore A, or in a range of densities, sheeting is available in a variety of grades to suit almost any application. Low to High Temp Silicone Sheeting Silicone sheeting performs at a wide range of temperatures, with standard grades performing at temperatures from -60C to +230C, with high and low temperature grades also available. Where food, medical or pharmaceutical applications are required, FDA or metal detectable grades are available. Silex silicone sheeting can be supplied off the roll or converted into strips, seals, gaskets and fabricated products.

Silicone Hose Products

When the size range required exceeds the possibilities of extruded products or when wire reinforcement is required for vacuum applications, mandrel-built hoses can be a great alternative. Hoses of up to 300mm diameter can be produced, including platinum cured grades for pharmaceutical applications, peroxide cured coloured hoses for coolant, and various flame retardant and industrial grades for technical applications, including fluorosilicone lined hoses suitable for use with volatile fuels. Along with our large tube range, Silex stocks a selection of braided and reinforced hoses suitable for vacuum or pressure applications and our large coolant hose offering not only includes straight lengths and reducers but a range of elbows and straight connectors.

- Peroxide or Platinum cured options

- Vacuum hoses

- Pressure hoses

- Coolant hoses

- Fluorosilicone lined hoses

- Elbows and straight connectors

Silicone Seals, Washers & Gasket Products

The fabrication department at Silex has an extensive range of machinery for cutting gaskets and silicone seals from solid and sponge sheet and washers and sleeves from tubing. Excellent tolerance bands on dimensional aspects are guaranteed. Silex also manufactures joined silicone seals from extruded sections and cords with a variety of special fabrications and assemblies, sometimes incorporating non-silicone items such as valves or connectors. The Silex portfolio includes hot and cold adhesive bonding, mitre corner bonding and our film joining technique.

Silex's fabrication department offers a range of services for producing seals, washers and gaskets to tight tolerances.

- Waterjet Cutting - a very precise solution for even small batch productions. All we need is a drawing.

- Blade Cutting - a low cost, high precision method of producing gaskets and washers to either hand-cut or punch washers, seals or gaskets.

- Pressure Sensitive Adhesive Backing - PSA backing can be applied to any flat surface quickly and cost-efficiently.

- Assembly with Non-Silicone Items - such as valves and connectors.

- Film Joining - Using a film of silicone rubber compound and curing with pressure and heat to form an extremely strong joint.

- Cold Adhesive Bonding - Using a silicone adhesive to bond items.

- Mitre Corner Bonding - A precise method of bonding corners, popular for seals and gaskets for angled surfaces.

- Moulding - producing moulded seals, washers and gaskets (rather than cutting or punching from sheet) with exceptionally precise, clean edges.

Exceptional Performance Across Industries

Engineered with precision, SILEX Limited's silicone solutions meet stringent standards for medical, pharmaceutical, food processing, laboratory, and electrical insulation requirements. Their superior tensile strength, dielectric properties, and virtually zero water absorption make them a reliable choice for demanding environments.

Customisation and Versatility

Customers can choose from a variety of colors, hardness levels, and customizable formats. Whether you need flat sheets, hoses, or intricate gasket profiles, SILEX supplies silicone products tailored to specific dimensions, tolerances, and applications, including both platinum and peroxide curing processes.

Advantages of SILEX Silicone

With an odorless, non-toxic, and non-stick surface, SILEX silicone products assure safety and performance. FDA-compliant grades are available for peace of mind in sensitive fields. High-precision manufacturing ensures consistent quality, making these products ideal for both manufacturers and end-users across sectors.

FAQ's of SILEX Limited Silicone Sheeting, Hoses And Seals:

Q: What customisation options are available for SILEX silicone sheeting, hoses, and seals?

A: SILEX offers a variety of color options (translucent, red oxide, blue, and custom shades), hardness from 30 to 80 Shore A, and custom sizes, including thicknesses from 0.3 mm to 12 mm, outside diameters up to 1200 mm, and bespoke profiles. Individual bore and inside diameters are also made to order.Q: How do I select the right silicone product for my application?

A: Begin by identifying your operational environment. Consider temperature range, required hardness, dimensions, electrical insulation needs, and whether FDA compliance is necessary. SILEX's team can assist with selecting the optimal material and format, ensuring you receive a tailored, high-performance solution.Q: When should FDA-compliant silicone grades be used?

A: FDA-compliant grades are recommended for applications in the food, beverage, and pharmaceutical industries or whenever contact with consumables or sensitive products occurs. These grades meet health and safety standards required for such environments.Q: Where are SILEX silicone products supplied from and can they be shipped internationally?

A: SILEX silicone products are manufactured in the United Kingdom. As a distributor, exporter, importer, supplier, and trader, SILEX provides international shipping to customers worldwide, ensuring timely delivery for global projects.Q: What are the benefits of platinum and peroxide cured silicone rubbers?

A: Platinum cured silicone offers increased purity, consistency, and reduced volatile compounds, making it ideal for medical and food-grade uses. Peroxide curing provides robust mechanical strength. Both types are non-toxic, non-stick, and deliver reliable long-term performance.Q: How are SILEX silicone sheets and hoses commonly used?

A: Typical applications include medical devices, food processing equipment, pharmaceutical production, laboratory and research setups, gaskets, seals, and electrical insulation. Their high dielectric strength and non-reactivity make them suitable for diverse, precision-driven environments.Q: What is the process for ordering a custom silicone product from SILEX?

A: To order a custom product, provide your specifications (dimensions, color, hardness, shape, and any compliance requirements). SILEX's technical team will guide you through design, material selection, and production. An accurate quotation and timeline will be provided before proceeding with manufacturing and delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Bearings Category

PTI Bearings And Transmissions

Price 3500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome steel

Structure : Deep Groove

Bearing Type : Ball Bearing

Lubrication Type : Grease

ELESA and GANTER

Price 900 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Other, Bearings Steel (GCr15)

Structure : Single Row Deep Groove

Bearing Type : Other, Deep Groove Ball Bearing

Lubrication Type : Grease

AEGIS SGR Bearing Protection Ring

Price 75000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Special conductive microfibers, Aluminum housing

Structure : Ring Type

Bearing Type : Other, SGR Bearing Protection Ring

Lubrication Type : Other, Not Lubricated

Tandem Thrust Bearings

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry