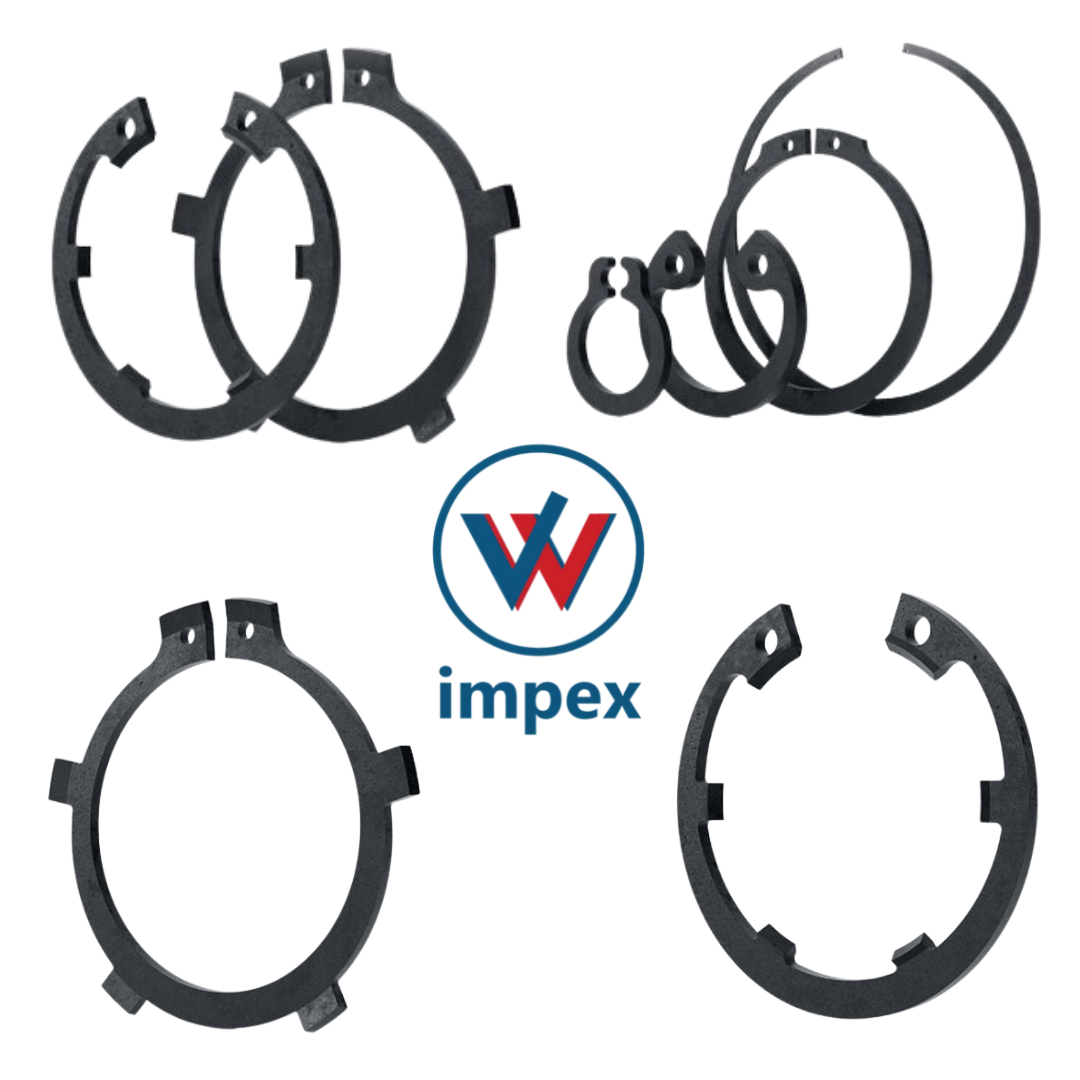

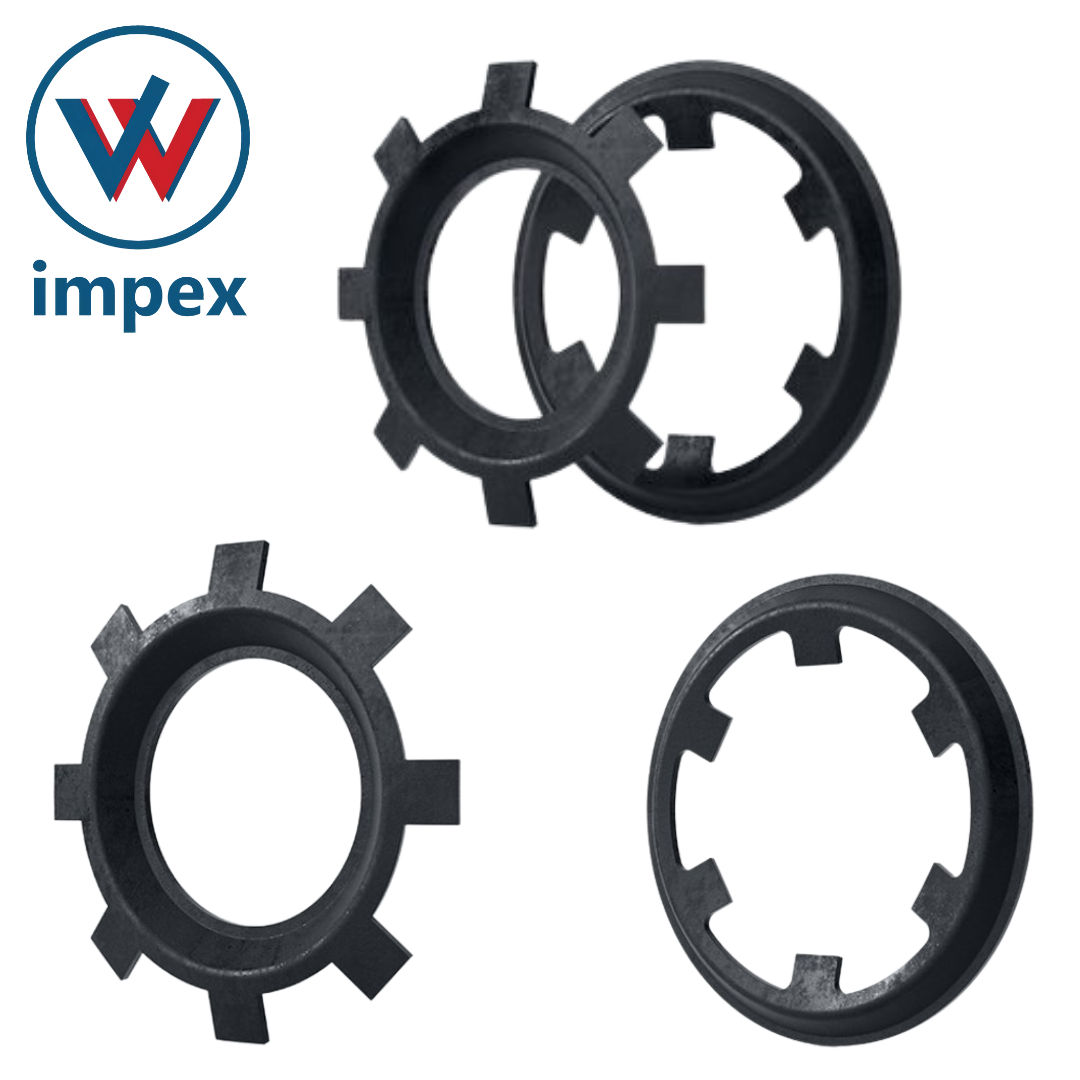

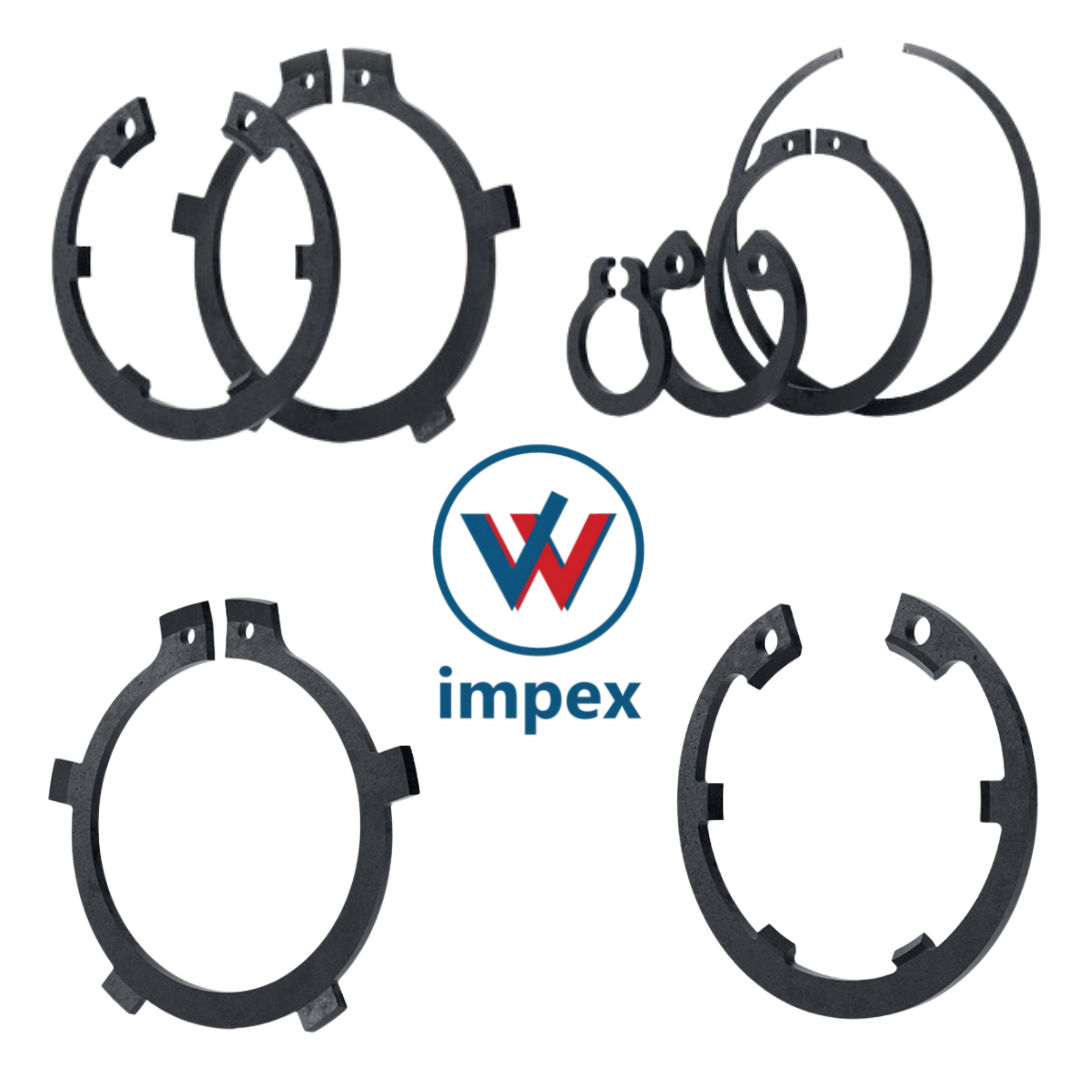

SEEGER CIRCLIPS Price And Quantity

- 500 INR/Piece

- 50 Piece

SEEGER CIRCLIPS Product Specifications

- Black

- 1-100

SEEGER CIRCLIPS Trade Information

- 100 Piece Per Week

- 5 Days

Product Description

SEEGER retaining systems are manufactured from high-grade spring steels which are selected on the basis of the special characteristics required for the various ring applications. The rings are hardened using the appropriate heat treatment processes (bainitic hardening or isothermal austempering) to enable them to absorb high axial forces when fitted in the groove, ensuring the rings can be assembled without any issues. It is interesting to note that larger rings have a lower hardness, because the stresses placed on them during assembly are not as high as the stresses placed on smaller rings. The hardness of rings is specified in terms of Rockwell or Vickers values depending upon ring size.

Carbon Spring Steel

Seeger-Orbis selects raw material based on its performance characteristics, such as a high modulus of elasticity, high yield point, high elastic elongation and good hardening abilities; which are best achieved by spring steels in accordance with DIN 17222. The material C75S, material No. 1.1248, is a good example. This is a high-purity carbon spring steel with a low phosphorus and sulphur content. This material, along with Mk 58 and spring steel wire in accordance with DIN 17223, are the primary steels used to manufacture Seeger retaining systems.

Special Materials

In addition to the above-mentioned carbon spring steels, corrosion-proof materials are also used. The following materials are also available to manufacture SEEGER retaining rings:

Corrosion-Resistant Stainless Steels

1. Designation: X 39 CrMo 17.1, Material Number 1.4122 As a hardenable martensitic chrome steel, this material does not have the resistance of austenitic chrome nickel steels, but it suffices for numerous applications and is used above all in the manufacture of smaller and medium-size rings.

2. Designation: X l2 CrNi 17.7, Material Number 1.4310 This material is an austenitic, corrosion-proof stainless steel which is particularly suitable for work hardening. Both SEEGER rings to DIN 471/472 with dimensions of more than 100 mm nominal diameter (concentric form) and snap rings SW/SB can be manufactured from this material.

Note:

All stainless steels are susceptible to specific types of corrosion, which in certain circumstances, may lead to sudden failure of the ring assembly due to brittle fracture. It is absolutely necessary to pay attention to the specific characteristics of these materials when used in conjunction with certain corrosive media. The risk of stress corrosion can be minimized by reducing the tension. Therefore, the depths of the grooves should be designed in such a way that the rings are assembled with a minimum of pretension.

Tin Bronze CuSn8, Material Number: 2.1020.34, DIN 17662 Although it has a high strength, this material has a lower elastic deformation than spring steel. Therefore, rings manufactured from this bronze tend toward plastic deformations in the higher-stress smaller dimensions; although, a tight fit in the groove is almost always guaranteed. In comparison with spring steel, this material's lower modulus of elasticity (115.000 N/mm square) results in a reduction in its load bearing capacity and its detaching speed. However, tin bronze is antimagnetic, and even at low temperatures, shows no tendencies towards embrittlement.

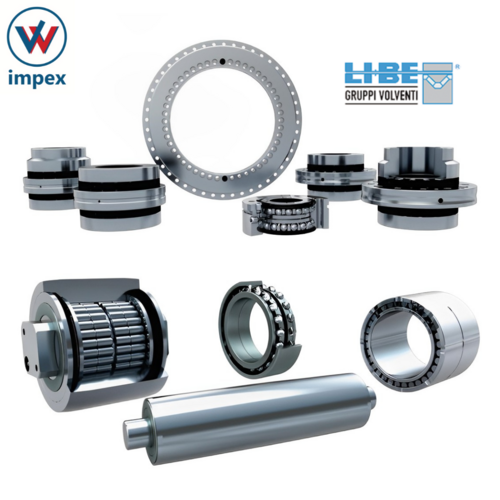

Other Products in 'Special Bearings' category

|

V. W. IMPEX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry