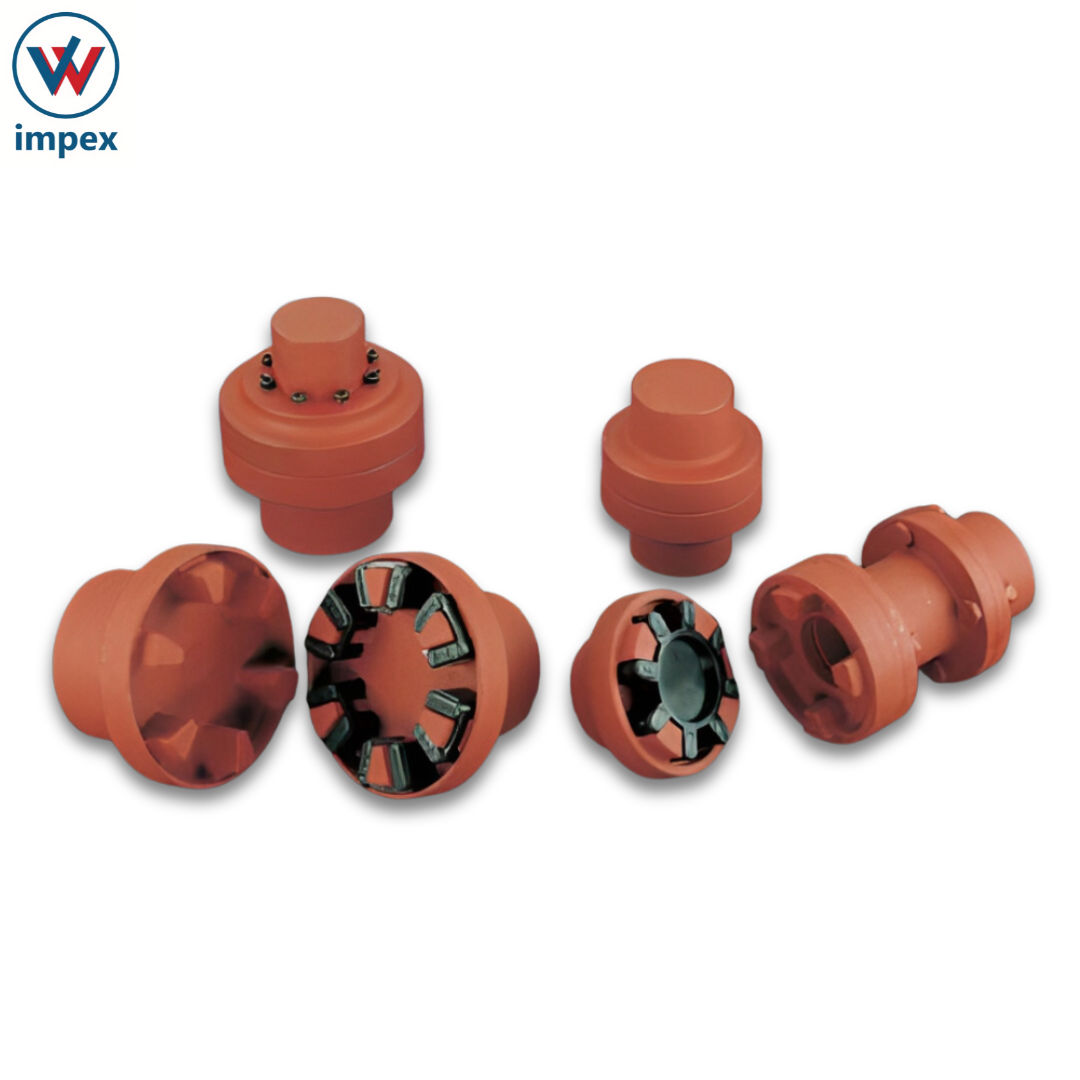

RU-STEEL Flexible Couplings

Product Details:

RU-STEEL Flexible Couplings Price And Quantity

- 15000 INR/Piece

- 1 Piece

Product Description

RU-STEEL Italia S.R.L. is a medium companyspecialized in the field of the transmission couplings, from its first times(1958), the company is grown, step by step, increasing their capacitiestogether in designing and manufacturing transmission couplings.

Since the first coupling produced, RU-STEEL™s philosophyhas been designing and manufacturing a complete range of transmission couplings(from Nm 3 to 300.000, including "elastic couplings, "self-lubricatingcoupling, "flexible couplings, "super elastic coupling) in order to meet allcustomer™s requests.

TYPES OF RU-STEEL COUPLINGS

1) ELASTIC COUPLING - The RU-STEEL elasticcoupling is composed with two equal gear rings, whose teeth engage themselvesrespectively with interposition of high resistance resilient blocks, which workonly by compression. The use of RU-STEEL coupling assures the relief ofincidental little misalignments between the connected shafts, which may depend,for instance, on unavoidable mistakes in the assembly, on thermic expansion, onelasticity of supporting structures, on ground settling, or on other causes.Furthermore the said coupling cushions the transmission of axial thrustsbetween the two connected shafts, because of its structural characteristics.G250 cast iron execution with 80Sh oil-resistant rubber plugs. It offers anelastic transmission by absorbing any shocks or vibrations, available invarious lengths and sizes. It can work from -30 C to + 120 C.

2) SELF-LUBRICATING GEAR COUPLINGS -The coupling of the "GD set has got the main characteristic in the gears madeby elements easily changeable in very strong resistance and self-lubricatingmaterial, while it intensifies the softness of the transmission, also avoids afurther lubrication. The mentioned elements intersect each other into boresmade half on the outer annulus gear and half on the inner hub. In that way thetwo edges, the inside of the annulus gear and the outside of the hub, can becompared to cogged surfaces and the driving elements, placed between the twoconstant-mesh gears, work as solid lubricating. Furthermore, the gear couplingof the "GD set owns the capacity of working in both directions of rotation andwith reversible of rotation and allows vertical and blind assembly. Executionin three pieces, completely metal in C 45 UNI EN ISO 10083/1/93, with cylindersin Teflon or bronze. These materials called "self-lubricating" allowaxial sliding during the transmission of power.

3) FLOATING TEETH COUPLING (ZEUS) -RU-STEEL couplings with floating teeth type "ZEUS are designed andmanufactured to join two rotating shafts by transmitting a torque in atorsionally rigid way. They are totally manufactured in carbon steel "C 45,they are composed by some hubs, produced with a "SPHERIC toothing and byflanged coupling sleeves with a "CYLINDRICAL toothing. The torque istransmitted by the mutual engagement of the toothing™s junction of the flangesthrough some gauged bolts. Full steel execution in C 45 UNI EN ISO 10083/1/93.High transmission torques with small dimensions.

4) RIGID COUPLINGS - Execution in cast ironG250 UNI ISO 185. Useful for connecting particularly long shafts of the samediameter, both with and without key. Completely rigid transmission.

5) FLEXIBLE ALL STEEL COUPLINGS - Fullsteel execution in C 45 UNI EN ISO 10083/1/93, with reinforced lamellar packsin AISI 304 10083/1/97 stainless steel, flexible but torsionally rigid, withoutspacer, ATEX certified.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Couplings & Gears' category

|

V. W. IMPEX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry