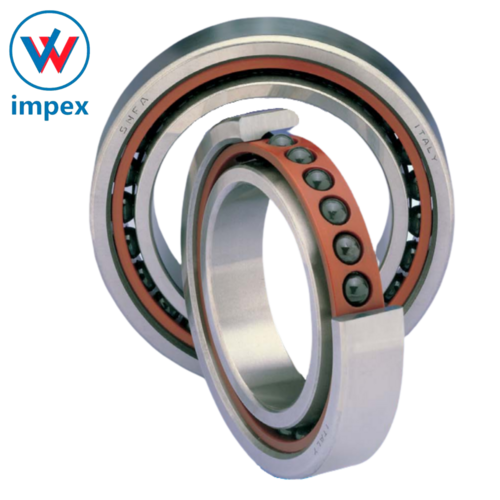

NTN Super Precision Bearings

Product Details:

NTN Super Precision Bearings Price And Quantity

- 10000 INR/Piece

- 2 Piece

Product Description

NTN offers a wide range of Precision Angular Contact Ball Bearings for use in high speed machining. These product designs are manufactured to address both radial & thrust loads while still maintaining speed requirements needed for metalworking and other machining processes. These designs are normally found in CNC spindles which are critical for maintaining tight tolerances to achieve proper finished goods in manufacturing.Precision Cylindrical Roller Bearings are essential in spindle designs utilized in the manufacturing marketplace. Both single and double row precision cylindrical roller bearing designs are manufactured with tighter tolerances and clearance options to maintain efficient finished goods. Cylindrical rollers bearings are required where thrust loads and rigidity are present in the machining process.

Precision Taper Roller Bearings are utilized within some CNC machining processes. They are found in small spindle designs that require heavy thrust load capabilities. They also can be found in other machining functions not related to the primary spindle itself. Their precision taper rollers are manufactured with tighter tolerances to maintain proper functionality.

The rigidity of the main spindle of a machine tool is associated with both bearing rigidity and shaft rigidity. Bearing rigidity is typically governed by the elastic deformation between the rolling elements and raceway surface under load. Usually, bearings are preloaded in order to increase the rigidity. Under same loading conditions, a roller bearing has a higher rigidity than a ball bearing of the same size.

NTN High Precision Bearings combine leading technology and the expertise of a global leader to optimize the performance of your machine. The range of precision bearings has been developed by NTN experts in close collaboration with some of the biggest names in machine tools. The benefit of the range:

Productivity: optimized production cost

Accuracy: high-quality machining

Reliability: reduced maintenance costs

Eco-Design: environmental protection

The range features the ULTAGE label, proof of its ultimate performance.

Spindle Bearings

High Precision Angular contact ball bearings - Standard, High-Speed and Ultra-high-speed

High precision cylindrical roller bearings with 1 or 2 rows of rollers - Standard and High-Speed

Angular Contact Ball Bearings for Axial loads

Ball Screw Support Bearings

BSTU - sealed

BST - open/sealed

Other Products in 'Precision Bearings' category

|

V. W. IMPEX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry