Call: 08045801215

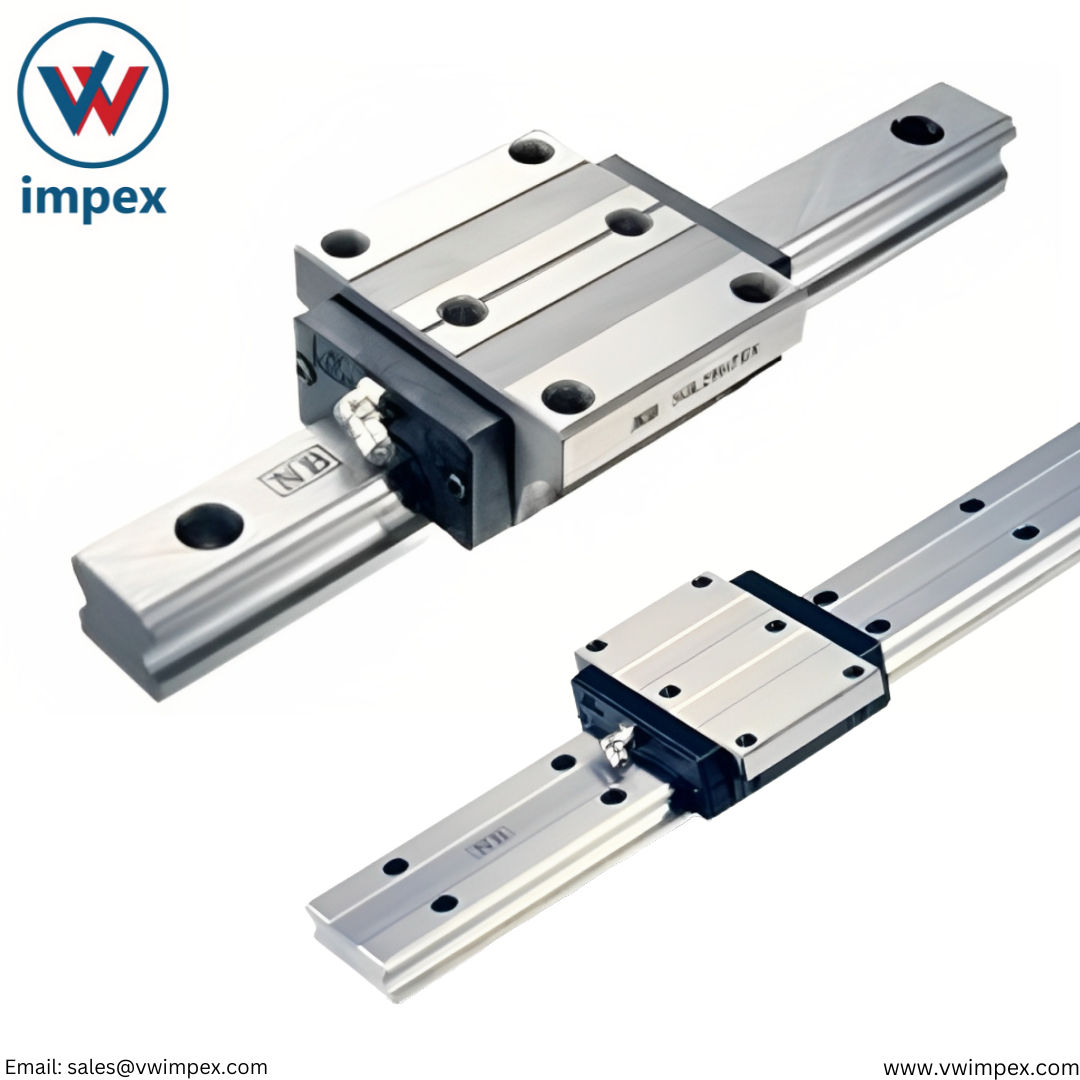

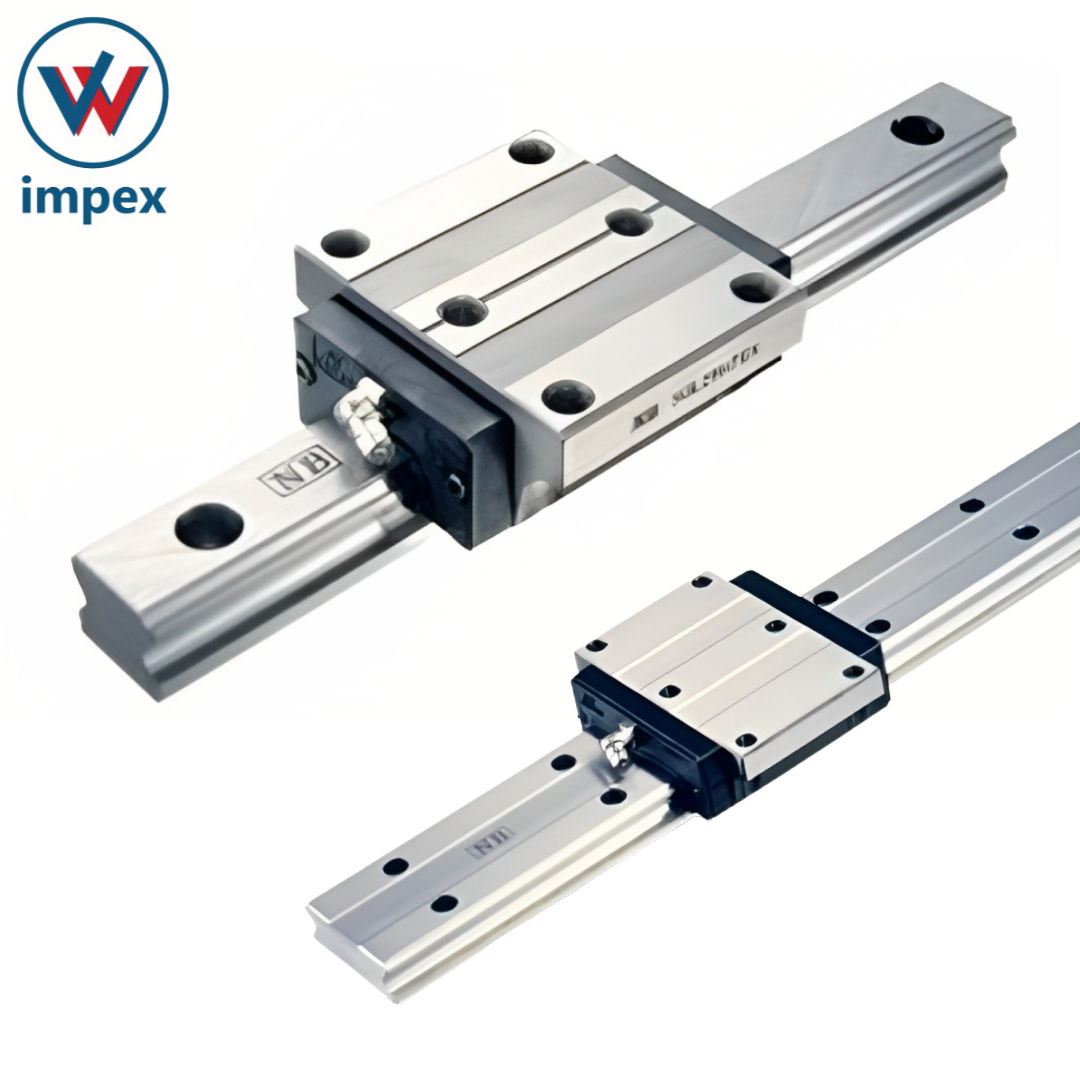

NB Linear Bearing

Price 2000 INR/ Piece

MOQ : 1 Piece

NB Linear Bearing Specification

- Thickness

- Depends on model

- Weight

- 50 g to 700 g

- Material

- Chrome Steel, Stainless Steel

- Ball Bearing Type

- Linear Ball Bearing

- Bushes Type

- LM Bush

- Structure

- Cylindrical, Open or Closed

- Seals Type

- Rubber Seals

- Number Of Rows

- Multiple Rows

- Bore Size

- 8 mm to 50 mm

- Outside Diameter

- 15 mm to 80 mm

- Limiting Speed

- Up to 5000 rpm

- Load Capacity

- Varies by model, up to 2000 N

- Inner Diameter

- 8 mm to 50 mm

- Maintenance

- Low, Easy Replacement

- Application

- CNC Machines, Automation, Robotics, Printing Machinery

- Precision Grade

- ISO Class 5, Class 7

- Lubrication

- Pre-lubricated, Re-lubrication possible

- Operating Temperature

- -20°C to +80°C

- Mounting Type

- Press fit or Retaining Ring

- Compatible Shaft Material

- Hardened Steel, Stainless Steel

- Corrosion Resistance

- Yes

About NB Linear Bearing

NB Linear Bearingis recognized as an international leader in the world of linear motion technology. Since its founding in 1939, NB has emerged as the leading manufacturer of high quality linear motion products in Japan, setting new international standards for performance and quality control industry wide. Their growth and high degree of product acceptance can be attributed to unique product designs, attention to detail and fresh approaches to meeting the linear motion needs of customers.The NB Linear Motion system is a linear motion mechanism which utilizes the recirculating movement of ball or roller elements to provide smooth and accurate linear travel. NB offers a wide range of linear motion products that may contribute to the size and weight reduction of machinery and other equipment, while providing dependable performance in high-precision equipment.

Slide Guide:

- Ball spline-rotary ball spline-stroke ball spline

- Stroke bush slide rotary bush

- Shaft

- Slide way slide table-miniature slide

- Actuator

- Slide screw

Precision Performance for Demanding Applications

Our NB Linear Bearings deliver outstanding performance in CNC, robotics, and advanced automation. Engineered to ISO Class 5 and 7 precision grades, these bearings ensure repeatable, accurate motion in environments where every micron matters. Multiple rows of linear balls, open or closed bush options, and a choice between chrome steel or stainless steel construction make them highly versatile for sophisticated machinery.

Designed for Longevity and Reliability

Built with robust corrosion resistance, these linear bearings are pre-lubricated for smooth initial operation and allow for simple re-lubrication, extending useful life. The rubber seal structure keeps contaminants out, and their low-maintenance design means less downtime during operation. Easy replacement and press-fit or retaining ring mounting further enhance user convenience.

FAQs of NB Linear Bearing:

Q: How do I select the appropriate NB Linear Bearing for my application?

A: Selection depends on your applications bore size (850 mm), load requirement (up to 2000 N), operating environment, and shaft compatibility (hardened steel or stainless steel). Consider the required precision grade (ISO Class 5 or 7) and whether you need an open or closed bush structure.Q: What are the installation options for these linear bearings?

A: NB Linear Bearings can be installed using either a press fit method or secured with a retaining ring, offering flexibility based on your machines design and ease of maintenance requirements.Q: When should I perform re-lubrication on these bearings?

A: While each NB Linear Bearing is pre-lubricated for immediate use, re-lubrication intervals will depend on operating speed, environment, and load. For optimal performance and longevity, consult maintenance schedules or monitor for signs of increased friction or noise.Q: Where can NB Linear Bearings be used?

A: These bearings are ideal for applications in CNC machinery, automation lines, robotics, and printing equipment. Their corrosion-resistant materials and robust sealing allow usage in demanding industrial settings.Q: What is the benefit of the ISO Class 5 and Class 7 precision grades?

A: ISO Class 5 and 7 precision grades ensure high accuracy and smooth movement, which are crucial for precision critical applications such as CNC machining, where tight tolerances must consistently be maintained.Q: How does the cylindrical, multi-row structure enhance performance?

A: The cylindrical, multi-row design distributes load efficiently and provides consistent, smooth linear motion. This results in improved load capacity, reduced wear, and reliable operation even at high speeds up to 5000 rpm.Q: What maintenance advantages do NB Linear Bearings offer?

A: With their pre-lubricated design, low maintenance requirements, and easy replacement process, NB Linear Bearings reduce downtime and simplify routine upkeep, contributing to higher productivity and lower overall operating costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

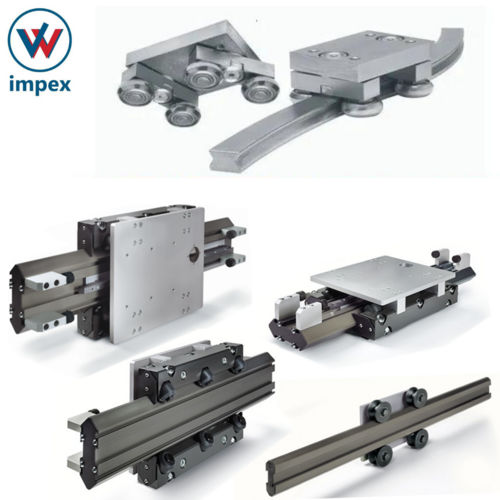

More Products in Linear Motion Category

Steinel Guide Units

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Alloy Steel / Hardened Steel

Outside Diameter : 16 mm 100 mm

Weight : From 0.2 kg to 10 kg

Thickness : 3 mm 20 mm

Rollon Linear Rail

Price 9500 INR / Piece

Minimum Order Quantity : 1 ,

Material : Steel

Outside Diameter : 32 mm

Weight : 1.8 kg/m

Thickness : 22 mm

FRANKE LINEAR GUIDES

Price 6500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Aluminum, Steel

Outside Diameter : Customizable

Weight : Lightweight design

Thickness : Compact crosssection

Rollico Flat Cages with Needle Roller and Balls

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry