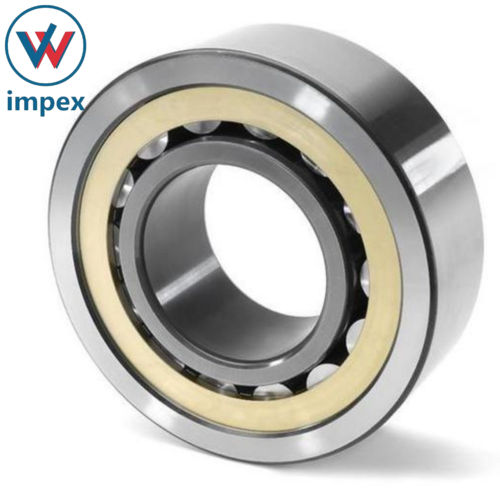

JNS Needle Roller Bearings and Roller Followers

Product Details:

- Size 10 MM TO 50 MM

- Usage INDUSTRIAL

- Click to View more

JNS Needle Roller Bearings and Roller Followers Price And Quantity

- 350 INR/Piece

- 2 Piece

JNS Needle Roller Bearings and Roller Followers Product Specifications

- INDUSTRIAL

- 10 MM TO 50 MM

Product Description

Needle Roller Bearings

Machined type needle roller bearings are high precision bearings which consist of machined outer ring with a complement of needle rollers retained and guided by a cage. The bearings feature a smaller cross-section, higher load-carrying capacity, greater rigidity. Therefore, they are useful in making machinery smaller and lighter.

* MACHINED RING NEEDLE ROLLER BEARINGS

* SEPARABLE NEEDLE ROLLER BEARINGS

The outer ring, needle roller and cage assembly, and inner ring are separable. Also, by selection of each part, the radial clearance can be easily adjusted.

* COMBINED NEEDLE ROLLER BEARINGS

The bearings consist of a radial needle roller bearing combined with a thrust ball bearing. They are capable of supporting both radial and axial loads.

* INNER RINGS

In case the shaft of one cannot be used as a raceway, inner rings are used to enhance the surface roughness and hardness of the shaft. Also, they can be used as bushes.

Stainless Needle Roller Bearings

Only in the world, JNS manufactures stainless steel needle roller bearings with excellent corrosion resistance. They are used in industries which require a high level of corrosion resistance, such as medical device, food machinery, and packaging machinery.

* MACHINED RING NEEDLE ROLLER BEARINGS

* INNER RINGS

Roller Followers

Outer ring is designed to have direct contact on the race. The thick outer ring is capable of bearing both large radial load and impact load while keeping direct contact with the guiding surface.

* SEPARABLE TYPE

Cage with needle rollers, outer ring, inner ring, and side shields are all separable.

* NON-SEPARABLE TYPE

Cage with needle rollers, side plate side shield, outer ring and inner ring are mounted together.

* FULL COMPLEMENT DOUBLE ROW TYPE

Double row design is adopted to withstand high radical load.

STAINLESS ROLLER FOLLOWERS

Stainless steel that has superior anti-rust and anti-corrosion ability is adopted. This type of bearing is used when corrosion resistance is needed, for example, in clean room and vacuum environment.

Formed in 1961, Japan Nose Seiko is one of Japan's premier manufacturers of needle roller bearings (metric) and cam follower bearings (including miniature cam followers). Products include machined needle roller bearings, cam followers, roller followers, and engineered specials.

* All products offered in chrome and stainless steel

* Products available in S0-S4 heat treatment

* Produces for major bearing manufacturer

* JNS "Factory of the Future" is outfitted with a production system incorporating state-of-the-art equipment and intelligent functions

* Bearings feature high precision as well as superior rigidity and durability

* Products favourable in industries such as automotive, construction, robotics, semiconductor, and steel mill applications

* Focus is on continuous caster and other steel mill related applications

Other Products in 'Roller Bearings' category

|

V. W. IMPEX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry