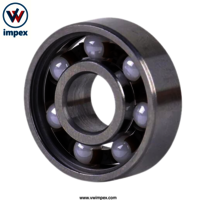

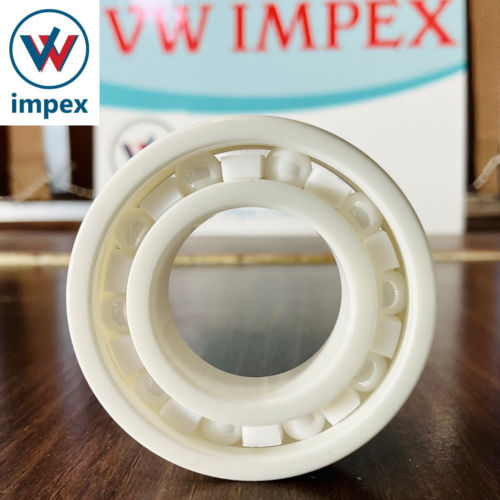

Hybrid Ceramic Bearings

Product Details:

Hybrid Ceramic Bearings Price And Quantity

- 6500 INR/Piece

- 1 Piece

Hybrid Ceramic Bearings Trade Information

- Days

- Yes

Product Description

Hybrid Bearings are made of (ZrO2 or Si3N4 balls + PEEK cage) ceramic ball bearing, inner ring and outer ring are made by metal, GCr15 or AISI440C. Hybrid ceramic ball bearings are an excellent choice for high speed applications. A ceramic (silicon nitride) ball weighs less than a steel ball, is stiffer, and has a near-perfect geometry and superior surface finish. These properties enable a bearing to operate at higher speeds and reduced temperatures with less wear. Ceramic ball have the following performance as low density, high strength, low friction, wear resistance, self-lubrication and higher rigidity, it's the best choice for rollers of the hybrid construction ceramic which are used in high-speed, high-precision and long life applications. Noise and vibration levels are also kept to a minimum. Furthermore, ceramic balls are corrosion resistant, nonmagnetic, and able to withstand repeated autoclaving, which makes hybrid ceramic ball bearings a good choice for medical and dental applications. If you want to extend bearing operational life, especially under conditions of marginal lubrication.

Specification:

SR144ZTR3S - SR type, Toron cage, 3S Si3N4 ball, 3.175 x 6.35 x 2.38

SRF144ZTR3S - SRF Flange type, Toron cage, 3S Si3N4 ball, 3.175 x 6.35 x 2.38, Z type

SR144ZTR3SWG - SR type, Toron cage, 3S Si3N4 ball, 3.175 x 6.35 x 2.78,Grooved,Z type

SRF144ZTR3SW - SRF Flange type, Toron cage, 3S Si3N4 ball, 3.175 x 6.35 x 2.78, Z type

SR144ZTR3SW - SR type, Toron cage, 3S Si3N4 ball, 3.175 x 6.35 x 2.78, Z type

Other Products in 'Ceramic Bearings & Ceramic Balls' category

|

V. W. IMPEX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry