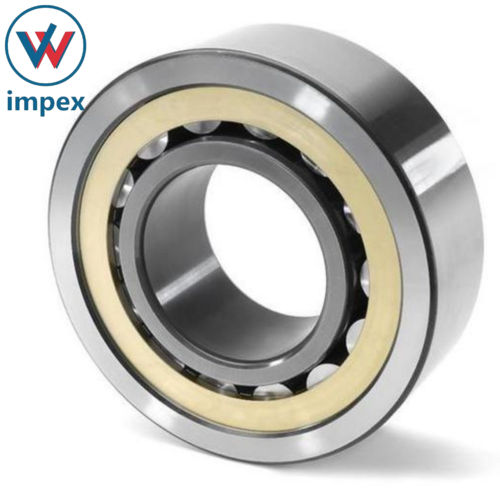

Gamet Bearings

Product Details:

Gamet Bearings Price And Quantity

- 25000 INR/Piece

- 1 Piece

Product Description

Gamet Bearings have been manufacturing high precision tapered roller bearings for over forty years in their Colchester factory. Originally founded to serve the machine tool industry, Gamet has today expanded into other sectors of industry having high precision bearing requirements.

These include the coating of materials, photographic emulsions or adhesives, and the printing and packaging industries. Ongoing investment in new equipment and technology will ensure the continuing reputation of Gamet as a manufacturer of high precision, high quality bearings.

PLAIN CUP

The basic single row bearing can be used in light to medium loaded applications, and provides a simple, cost-effective arrangement.

BENEFITS

- Cone Bore Run-out tolerances ranging from 0.5 microns to 1.5 microns

- Comprehensive range of sizes from 25mm bore upwards

- Quality assured to ISO 9000 standards

- High quality bearing materials

The flanged cup version enables through boring of the housing for simplicity and accuracy.

BENEFITS

- Cone Bore Run-out tolerances ranging from 0.5 microns to 1.5 microns

- Comprehensive range of sizes from 25mm bore upwards

- Quality assured to ISO 9000 standards

This single row bearing has an extended outer ring, housing a number of springs. It is mounted in conjunction with either a single or double row bearing. As the outer race is free to slide in the housing, the spring force ensures that a constant bearing system preload is maintained despite thermal expansion due to varying temperature conditions.

BENEFITS

- Specialist design and manufacturing service available to meet your particular requirements

- Competitive delivery on most sizes

Double row bearings offer nearly twice the capacity of the equivalent single row bearing, and are therefore used in more heavily loaded applications.

The plain outer race enables this bearing to be used in a 'floating' position to permit thermal expansion. As such it can replace a P type bearing when additional load capacity is required.

G type bearings can be pre adjusted to give GE double row bearings. This is achieved by fitting a spacer between the inner races to give the required assembly end play or pre load. The choice of setting is based upon a number of parameters such as speed, lubrication and applied loads. Spacer width is adjusted individually prior to despatch.

FLANGED CUP (H TYPE)

Double row bearings offer nearly twice the capacity of the equivalent single row bearing, and are therefore used in more heavily loaded applications.

This double row bearing has a flanged outer ring which locates the shaft axially. This can also simplify housing machining operations and overall design.

H type bearings can be pre adjusted to give HE double row bearings. This is achieved by fitting a spacer between the inner races to give the required assembly end play or pre load. The choice of setting is based upon a number of parameters such as speed, lubrication and applied loads. Spacer width is adjusted individually prior to despatch.

Other Products in 'Roller Bearings' category

|

V. W. IMPEX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry