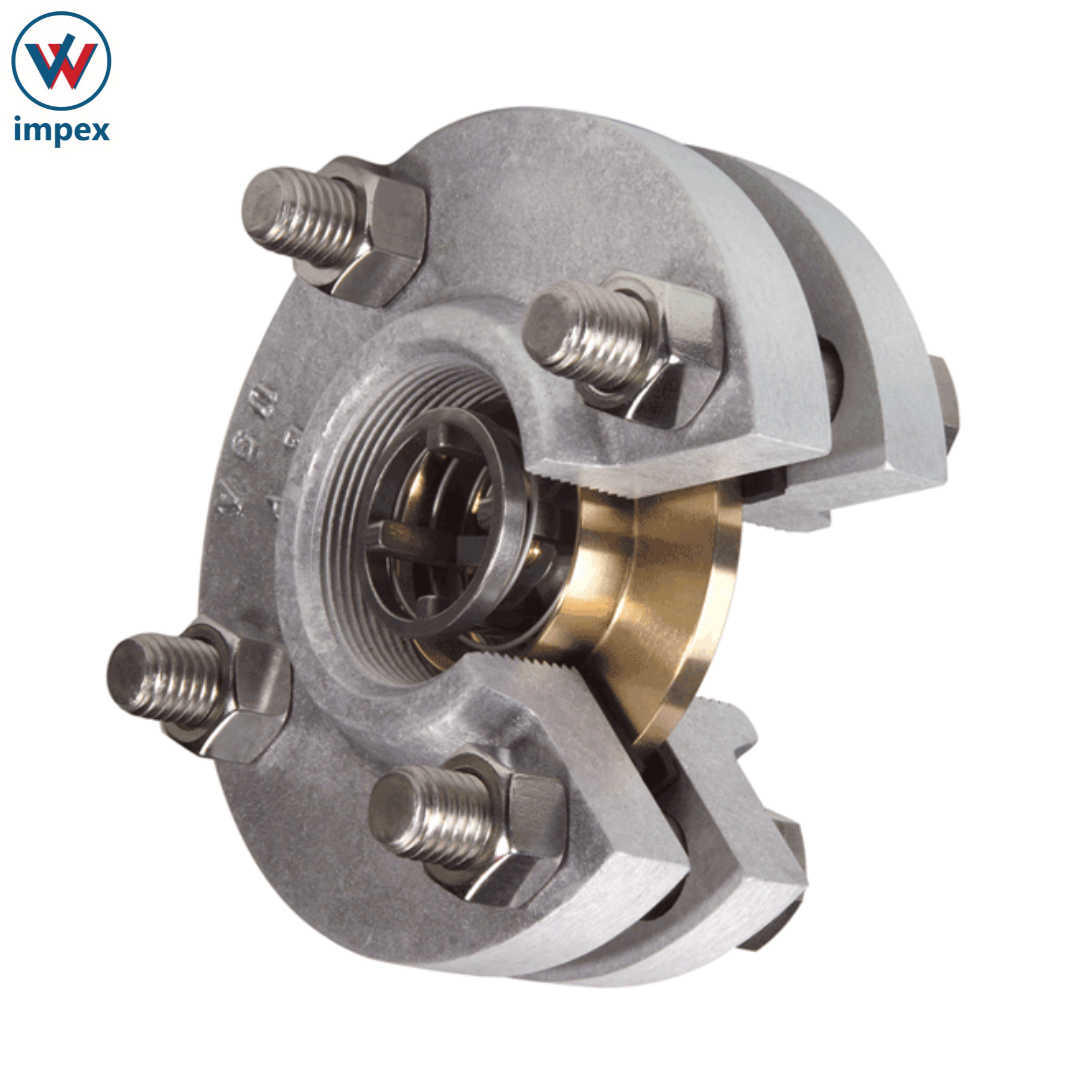

CheckALL Valve

Product Details:

CheckALL Valve Price And Quantity

- 2 Piece

- 8000 INR/Piece

Product Description

Since their inception in 1958, Check-All Valve has expanded from producing one valve with one material to manufacturing a series of valves in a wide range of materials. Many companies manufacture check valves in addition to other product lines; however, they are dedicated solely to the design and manufacture of check valves.

Check-All Valve produces a complete line of inline, spring-loaded, poppet-style check valves to serve a wide range of industries and practically every service application. Every Check-All valve is designed and built to perform to your exact needs and specifications. Their spring check valves are offered with metal-to-metal or soft seats in sizes ranging from 1/8 NPT to 20 flanged connections. Spring cracking pressures range from 1/8 PSI to 85 PSI and virtually any setting in between. Pressure ratings are available from full vacuum to 10,000 PSI with standard and exotic materials of construction also available.

Types of Check-All Valve:

1) Silent Check Valves - A silent check valve utilizes a spring to assist the poppet in closing the check valve prior to fluid flow reversal. This eliminates the hydraulic shock also known as water hammer. Water hammer is a result of the sudden stoppage of flow in a fluid process system.

2) Spring Loaded Check Valves - A spring loaded check valve (a.k.a. spring check valve) incorporates a spring to assist in closing the check valve. They are designed to close prior to fluid flow reversal. Preventing backflow eliminates the hydraulic shock also known as water hammer. Water hammer is a result of the sudden fluid stoppage of flow in a fluid process system.

3) Poppet Check Valves - A poppet check valve incorporates a disc (normally at the end of a "sleeve or "stem) utilized as the checking mechanism. It is often spring loaded to help close the valve prior to fluid flow reversal. This eliminates the hydraulic shock also known as water hammer. Water hammer is a result of the sudden fluid stoppage of flow in a fluid process system.

4) Inline Check Valves - Inline check valves utilize a check mechanism that functions in the fluid line or media pathway of a process piping system. Oftentimes, these check valves are of a compact design allowing for space saving and/or ease of installation into an existing system.

Styles of CheckValve :

1) Flange Connection

Flange Insert Check Valve Style “ F1, F6, FP

Horizontal, Vertical, Flanged & Drilled Style Check Valve “ HV

Wafer Insert Check Valve Style “ WV

2) Threaded Connection

Adapter Check Valve Style “ AM, AF

Bushing Check Valve Style “ BU, BR

Connector Check Valve Style “ CN, CR

Mini-Check Valve Style “ M1, M8

Universal High-Pressure Check Valve Style “ U1, R1

Universal Low-Pressure Check Valve Style “ U3, UR

3)Sanitary Connection

3-A Sanitary Check Valve Style “ 3S

Sanitary Cartridge Check Valve Style “ SC

Sanitary Insert Check Valve Style “ CB, TC

4) Welded Connection

Butt Weld Check Valve Style “ B4, B8

Universal Socket Weld Check Valve Style “ US

5) Tubing Connection

Tubing Check Valve Style “ TV

Tubing Check Valve, Flared Style “ TF

6) Lined Pipe Connection

Horizontal, Vertical, Flanged & Drilled PTFE Lined Style “ HT

Lined Pipe Insert Check Valve Style “ LP

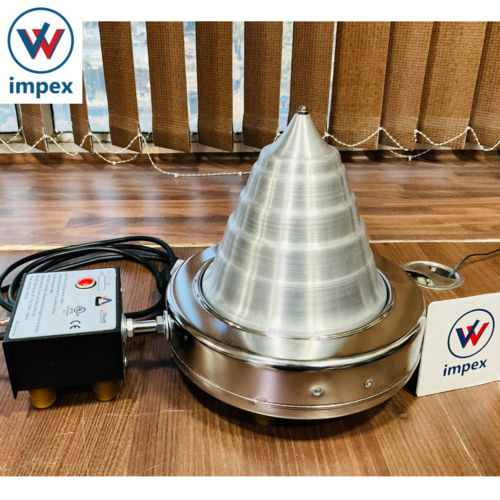

Other Products in 'Special Bearings' category

|

V. W. IMPEX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry