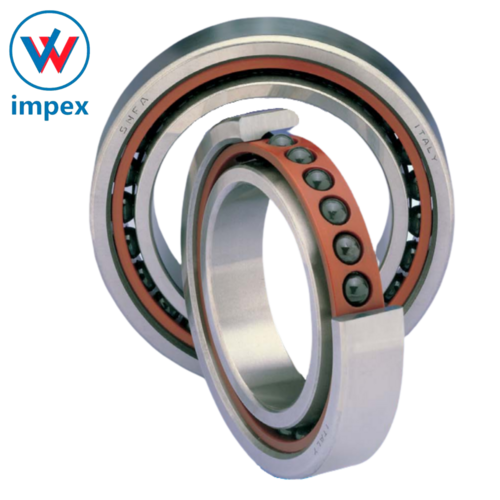

Barden Super Precision Bearing

Product Details:

- Color silver

- Usage Industrial

- Size Different Available

- Warranty Yes

- Click to View more

Barden Super Precision Bearing Price And Quantity

- 15000 INR/Piece

- 1 Piece

Barden Super Precision Bearing Product Specifications

- Different Available

- Yes

- Industrial

- silver

Barden Super Precision Bearing Trade Information

- 7 Days

Product Description

Barden is the pre-eminent leader in super precision ball bearing manufacturing in the world today. Barden Super Precision Bearing excel in applications where bearings of lesser quality have failed. If superior accuracy, reliability of operation, long-life, high running speeds and low noise and vibration are requirements in your application, Barden/FAG precision bearings are the bearings of choice.

These high speed super precision bearings are available with fibre cages, ceramic and small balls, or sealed.

Barden Angular contact bearings have one ring shoulder partially or totally removed. This allows a larger ball complement than found in comparable deep groove bearings, hence a greater load capacity. Speed capability is also greater.

Angular contact bearings are assembled to a contact angle by varying the radial clearance. Spindle size Barden angular contact bearings have nominal contact angles of either 15 degree or 25 degree. The smaller angle delivers better radial capacity and rigidity, the larger angle is better for axial rigidity.

Ball Screw Support Bearings:

Series L Ball screw support bearings are specially designed for high performance machine tools, where extreme rigidity requirements preclude the use of standard angular contact bearings. The internal configuration has been designed to provide an optimum combination of high rigidity, low drag and exceptional control of lateral runout and long life. Contact angle is high at 65 degree to provide axial rigidity and the very high thrust capacity.

Also available are the 7602, 7603 and BSB (15 mm width) series.

Spindle Bearings

Barden offers both Angular Contact and Deep Groove Spindle Bearings that are made to exacting Abec 7 or Abec 9 specifications, standards that Barden routinely exceeds.

Angular Contact bearings support thrust loads or combinations of radial and thrust loads in one direction while a deep groove spindle bearing can accept radial loads thrust loads (limited) in either direction or a combination of loads.

Instrument Ball Bearings

Barden offers both Angular contact and Deep Groove Instrument Bearings.

Angular Contact Instrument Bearings

Angular contact bearings have one ring shoulder partially or totally removed. This allows a larger ball complement than found in comparable deep groove bearings, hence a greater load capacity. Speed capability is also greater.

Angular contact bearings are assembled to a contact angle by varying the radial clearance. Instrument angular contact bearings have nominal contact angles of either 10 degree or 15 degree.

Separable and non-separable types are available. In a separable bearing (B type), the cage holds the balls in place so that the outer ring assembly (with cage and balls) can be separated from the inner ring.

Separable bearings are useful where bearings must be installed in blind holes or where press fits are required, both on the shaft and in the housing. The separable feature also permits dynamic balancing of a rotating component with inner ring mounted in place, apart from the outer ring and housing.

Angular contact bearings support thrust loads or combinations of radial and thrust loading. They cannot accept radial loads only - a thrust load of sufficient magnitude must be present. An individual angular contact bearing can be thrust-loaded in only one direction; this load may be a working load or a preload.

Deep Groove Instrument Bearings

Deep groove ball bearings have full shoulders on both sides of the raceways of the inner and outer rings. They can accept radial loads, thrust loads in either direction, or a combination of loads.

Other Products in 'Precision Bearings' category

|

V. W. IMPEX

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry